Semiconductor Micro-Inspection

Developing Machine Vision to inspect semiconductor defects in production.

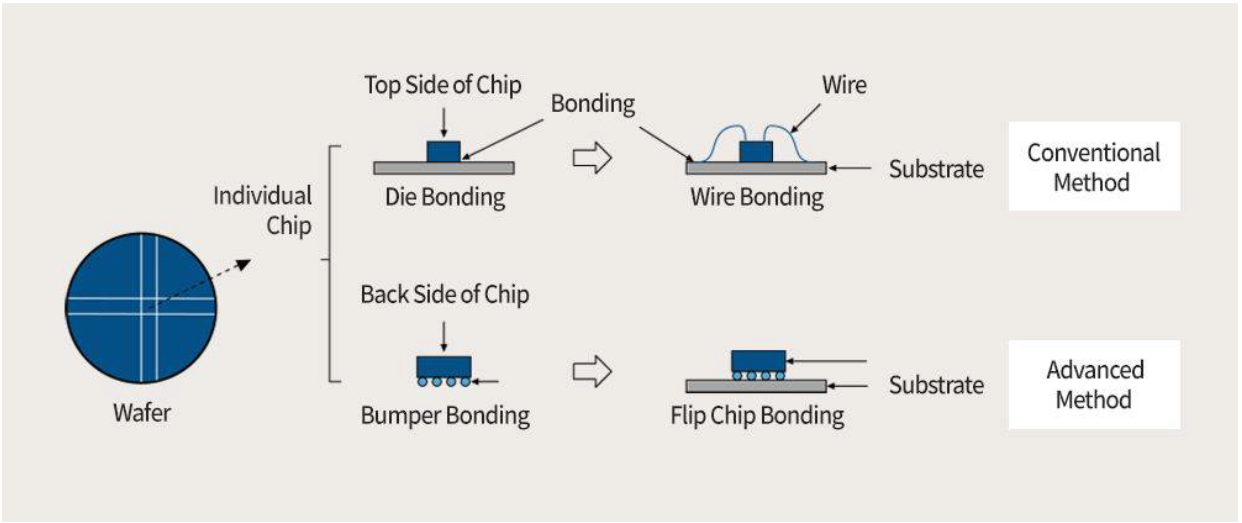

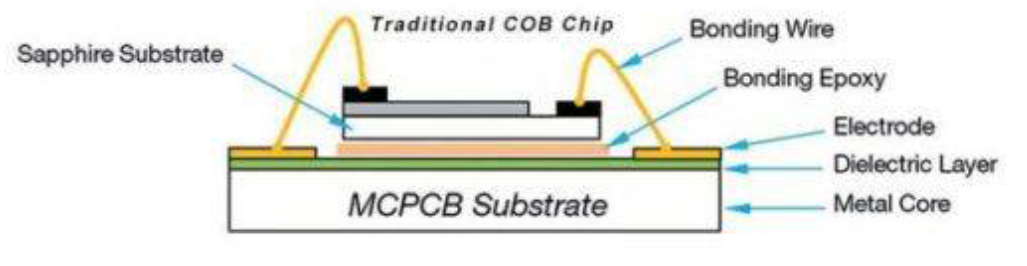

Chip bonding refers to a technique by which the individual chips of a wafer are attached to a substrate using an appropriate adhesive.

When necessary, it must maintain constant electrical conduction or realize a high level of insulation. Therefore, bonding methods are becoming more important as chips continue to become smaller and smaller.

There are many defects on:

- Substrate: contamination, displacement

- Chip: displacement, chip skew in 3D direction

- Pad (electrode) on chip and substrate: shape, location, displacement

- Epoxy: not fully covered the bonding area

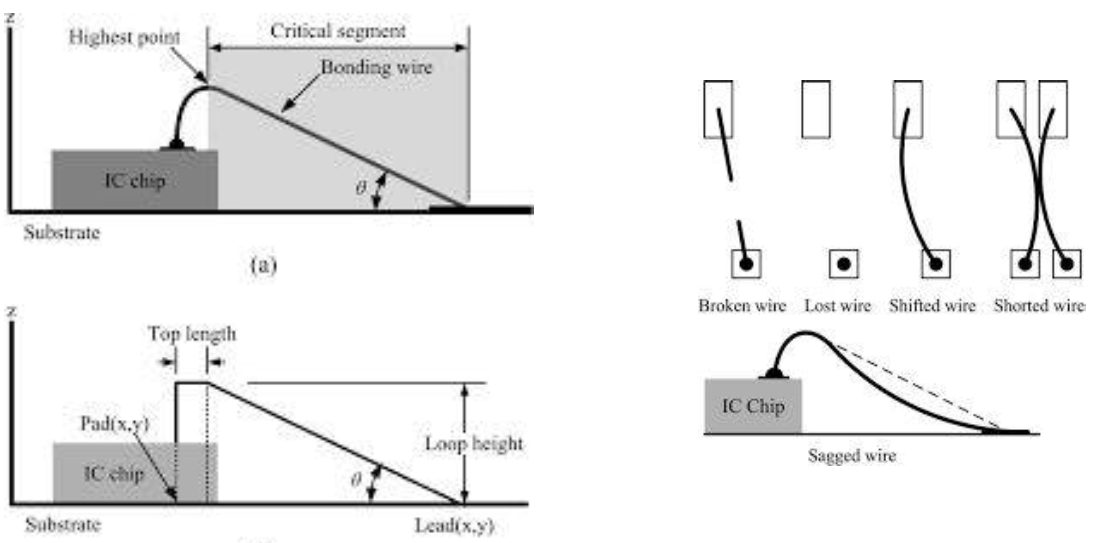

- Wire: looping, breaking, loop height, touching

Illustrated image:

System advantages:

- On-the-fly inspection

- Contactless measurement

- Detection Yield: 99.5%

- Measurement:

- Accuracy: 8 μm

- Repeatability: 4 μm

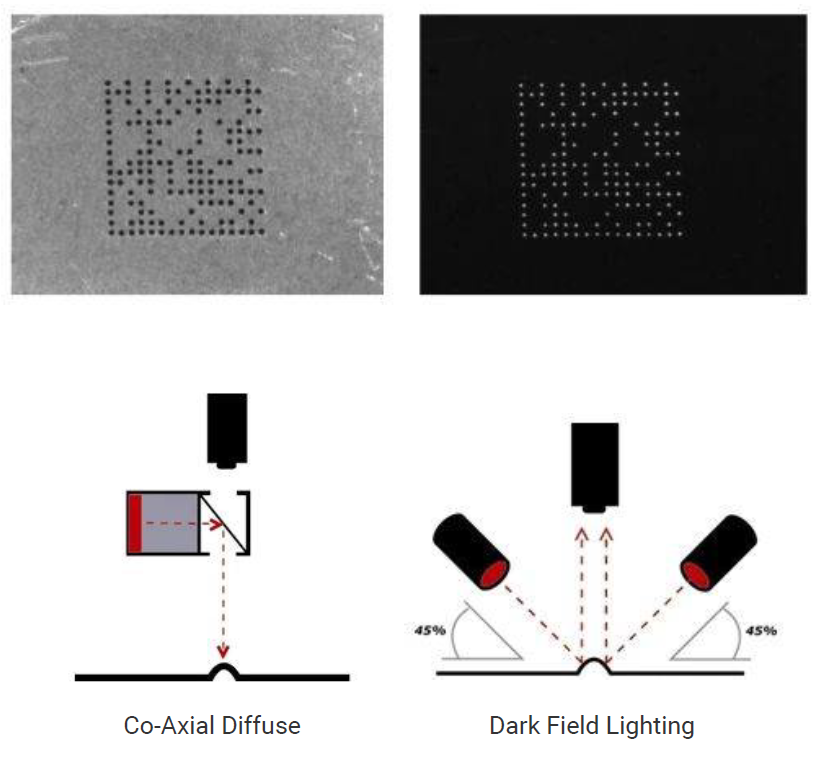

Illumination system

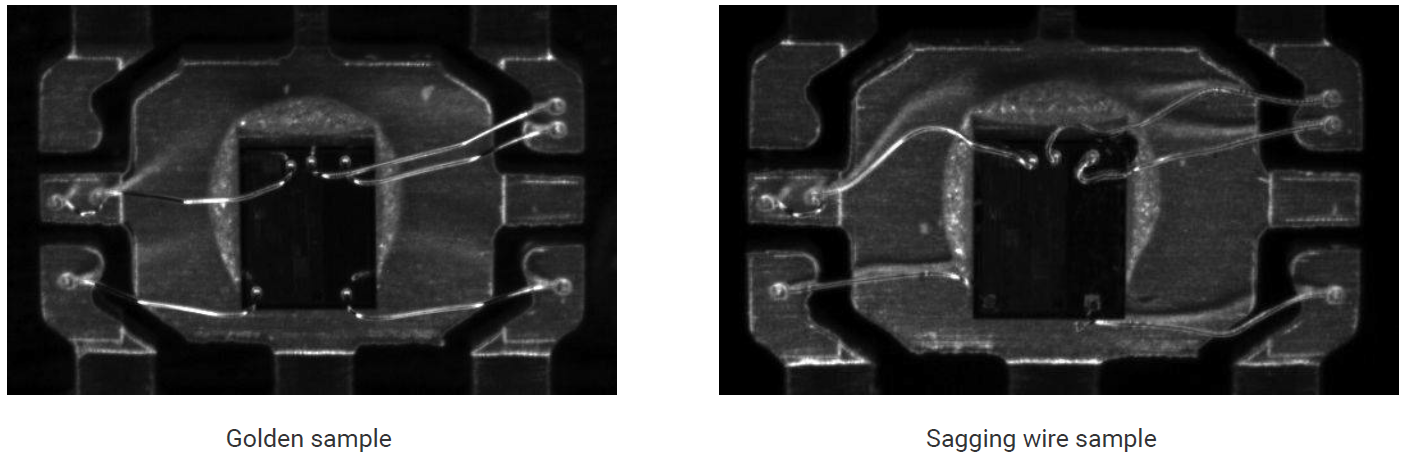

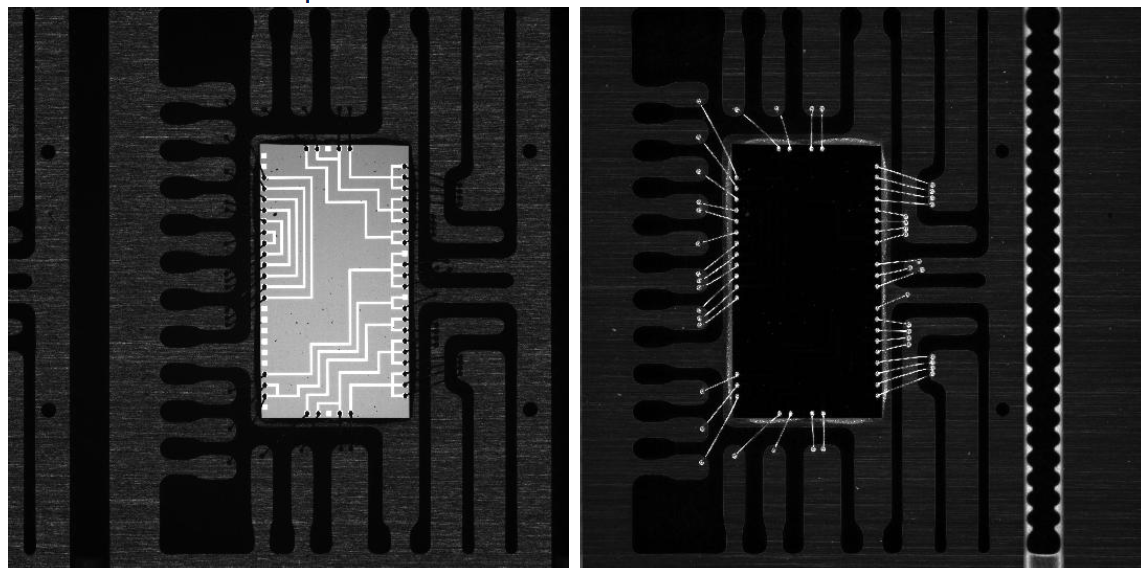

Actual samples:

Sagging wire samples: